ALPOLIC® Composite Metals

ALPOLIC® materials are ideal for architectural projects because they’re lighter in weight, easier to fabricate into complex forms, and easier to install than traditional materials. Yet they offer superior flatness, durability, stability, vibration damping and ease of maintenance. With a huge selection of finish types, colors and glosses – plus the ability to specify virtually any custom color – there’s no limit to the architectural effects you can create. To achieve the widest possible color and gloss range, with unmatched durability, we coil-coat our ACM sheets with the incredibly tough and stable Lumiflon® FEVE fluoropolymer resin, so your concept stays fresh through decades of exposure to the elements. ALPOLIC® products and finishes are backed by up to a 30-year warranty.

Product Properties

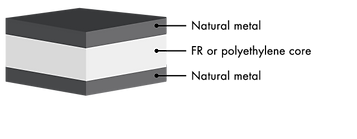

ALPOLIC® aluminum composite materials (ACM) are produced by continuously bonding two thin sheets of aluminum on either side of an extruded thermoplastic or mineral-filled, fire-retardant thermoplastic core. The aluminum surfaces have been pre-finished and coil-coated in a variety of paint finishes before bonding. We also offer metal composite materials (MCM) featuring skins of copper, zinc, stainless steel or titanium bonded to the same cores and left unfinished. ALPOLIC® ACM and MCM both offer the rigidity of heavy-gauge sheet metal in a lightweight composite material.

Ease of Fabrication

ALPOLIC® ACM can be fabricated with ordinary woodworking or metalworking tools, with no special tools required. Cutting, grooving, punching, drilling, bending, rolling and many other fabrication techniques can be easily performed to create a virtually unlimited variety of complex forms and shapes.

ALPOLIC®/PE

is an aluminum composite panel that is produced by laminating two thin panels of aluminum on either side of an extruded core of thermoplastic polyethylene material. These panels are offered in a wide variety of finishes and colors, featuring our advanced Lumiflon® FEVE resin in Valflon® coatings supplied by Valspar. We also offer a core of thermoplastic polyethylene material in our HD heavy-duty aluminum composite panel, RF reflective aluminum composite panel and a selection of natural metal composite panels.

ALPOLIC®/fr

is a fire-retardant panel composed of two thin panels of aluminum laminated to either side of a mineral-filled thermoplastic core. The aluminum surfaces have been coil-coated before bonding with an advanced Lumiflon® FEVE resin in a variety of finishes and colors, supplied by Sherwin -Williams Coil Coating (formerly Valspar). We also offer fire-retardant materials in our HD heavy-duty series and natural metal MCM composites.

ALPOLIC®/HD

Heavy-duty ALPOLIC®/HD heavy duty panels are the strongest, most rigid aluminum composite materials we offer – providing superior tensile and yield strength with over five times the flexural elasticity strength of our standard panels. These heavy duty panels incorporate skins of 0.032" aluminum sheet metal – 60 percent thicker than our standard aluminum skins. And they’re available with the same advanced Lumiflon® FEVE resin coatings, in Valflon® finishes supplied by Valspar, that make ALPOLIC® panels the most beautiful and durable aluminum composite materials you can specify.

ALPOLIC®/RF

provides a polished reflective aluminum surface suitable for many applications that require a high degree of reflectivity. A reflective aluminum panel is bonded to our PE core and backed by a second aluminum panel, creating a panel that’s much thinner and lighter than traditional options, much easier to fabricate and mount, and virtually unbreakable. It’s the perfect material for any architectural project or practical application where reflectivity is required but a heavy, breakable reflector would be a liability.

ALPOLIC® Brake Metal

offers a complement to our ACM products, giving fabricators the ability to form roof caps, flashing, fascia trim, accents and other complex forms using a sheet metal brake. This material is finished with Lumiflon® FEVE fluoropolymer resin in many of our most popular 4mm architectural stock colors and select specialty colors. Custom colors are also available when aluminum Brake Metal and matching ACM panels are ordered together and finished in the same special run.

Finishes

We offer an extensive selection of rich, vibrant colors and styles for both coil-coated paint and natural metal finishes. Our finish experts will help you get the exact look you envision. Let’s build.

Anodized Aluminum

Anodized aluminum is an exceptionally strong and impervious surface that brings a smooth sheen to your building. We bond anodized aluminum panels in a choice of six colors to the outer surface of these panels to create a material that is easy to fabricate, deeply lustrous and tough as nails. These anodized panels reveal the natural beauty of aluminum while enhancing its toughness and aesthetic possibilities.

Decorative Metals

ALPOLIC® decorative metal panels feature specially treated aluminum finishes on the outer skin of the panel, protected by a clear top coat. HPA has a polished, reflective shine. HLZ has a mechanically brushed surface that resembles brushed stainless steel. Both decorative metal finishes retain the flexibility and ease of fabrication of aluminum – a clear technology breakthrough for ALPOLIC®materials.

Matte Finishes

The warmly muted colors in our Matte Series panels evoke the calming hues of the natural world. These clay red, limestone blue, river rock grey, slate black, olive green and cloud white finishes draw inspiration from the landscape to root your building in a native sense of place.

Metallic Finishes

Our metallic panel finishes bring the look of silver, pewter, gold, steel, bronze, copper and other metals to our resilient aluminum composite panels. These finishes impart a luster of quality and distinction to your building – without the expense, fabrication difficulties and instability of natural metals. The durability and prestige of nature’s classic materials – with all the advantages that only modern ALPOLIC® composites can provide. That’s the timeless quality of our metallic finishes.

Mica Finishes

ALPOLIC® materials finished with a mica color in shades of silver, platinum, champagne, gray and anodic clear bring a sophisticated flair to your project. With embedded mica, panel colors take on a pearlescent warmth with a subtly dimensional appearance. It’s a look that catches the light, the eye and the imagination.

Multi-Color Finishes

Need multiple colors on a single panel? With our multi-color aluminum composite panels, you’re no longer limited to cheap-looking vinyl striped panels that only last a few years. Get all the quality and durability of our fluoropolymer painted panels with multiple stripes of precisely applied color. We have many multi-color panels stocked for immediate shipment, or we can create the custom combinations you need.

Natural Metal

Copper panels evolve and weather to a rich patina, adding beauty and depth to any building façade. Zinc panels offer an elegant matte patina. Titanium and stainless steel panels convey an image of high-tech sophistication like nothing else. Our natural metal finishes delivers the opulence of genuine metal at a fraction of the weight and cost of solid sheet alternatives.

Prismatic Finishes

To create our prismatic panels, we apply a uniquely scintillating finish that seems to subtly change colors with changes in the weather, time of day and viewing angle. Prismatic panels bring your building to life. With each passing moment, each angle, each person going by, it takes on a new look – compelling another, and yet another - making your architectural vision truly memorable.

Shimmer Finishes

Our new Shimmer Series finishes add mesmerizing silver or gold sparkles and rich, deep colors to our aluminum composite panels. The result is ideal for designs that require the boldest, most eye-catching details. And as always, you can count on the durability and reliability that come standard with ALPOLIC® composites.

Solid Color Finishes

These distinctive classics are available for immediate delivery in common architectural colors of white, gray, bronze and black, to bright program colors of rich reds, brilliant yellows and vibrant blues. We can also supply custom colors matched to virtually any color your project requires.

ALPOLIC® panels use Lumiflon® FEVE, a remarkable second-generation fluoropolymer coating that offers exceptional adhesion, weatherability and chemical resistance – in a full range of colors and glosses that ordinary PVDF paints can’t match.

ALPOLIC® materials are available for immediate delivery in a stunning range of solid colored panels, from stately architectural shades of white, gray, tan, bronze and black to bright program hues across the spectrum – rich reds, brilliant yellows, deep blues and more. We can also supply custom colors matched to virtually any color your project requires. Our Lumiflon® FEVE resin, in Valflon® coatings by Valspar, offers a full range of colors and glosses that ordinary PVDF paints can’t match.

Stone Series Finishes

Get the look of natural granite with our stone finish panels. This realistic finish replicates the imposing presence and intriguing grain patterns of polished granite on an aluminum composite panel that’s much lighter and more affordable. Aluminum composite materials are easy to fabricate for practically any interior or exterior application, and the advanced fluoropolymer finish is designed to keep the stone panel effect looking beautiful for decades.

Timber Series Finishes

The natural look of wood, without the weight, maintenance difficulties or expense. That’s what our Timber Series finishes are all about. These wood grain panels offer the rich beauty of Mahogany, Walnut, Maple, Zebrawood, Teak, Oriental Cane or Harvest Trail Bamboo in an aluminum composite material with an advanced fluoropolymer finish that’s far more durable than real wood. For both interior and exterior applications, our wood grain panels provide the outstanding natural appearance you’re looking for, along with the outstanding performance and value you expect from all ALPOLIC® .

For more information visit: http://www.alpolic-americas.com/products